SPOILER ALERT!

Tunnel Pasteurizers Are Highly-Effective Pasteurization Solutions For Foods As Well As Drinks

https://www.foodsafetynews.com/2012/11/are-pasteurized-cantaloupes-the-answer-to-killer-cantaloupes/ -Russell Overby

They are ergonomic and lasting, as well as they utilize an unique control software to maximize effectiveness as well as lower water use. This makes sure a high level of sanitary performance. The compact design supplies very easy availability to the parts, allowing for very easy cleaning and also substitute of inlet displays. Tunnel Pasteurizers can additionally be made use of in mix with hot filling up techniques, consisting of warm filling innovation.

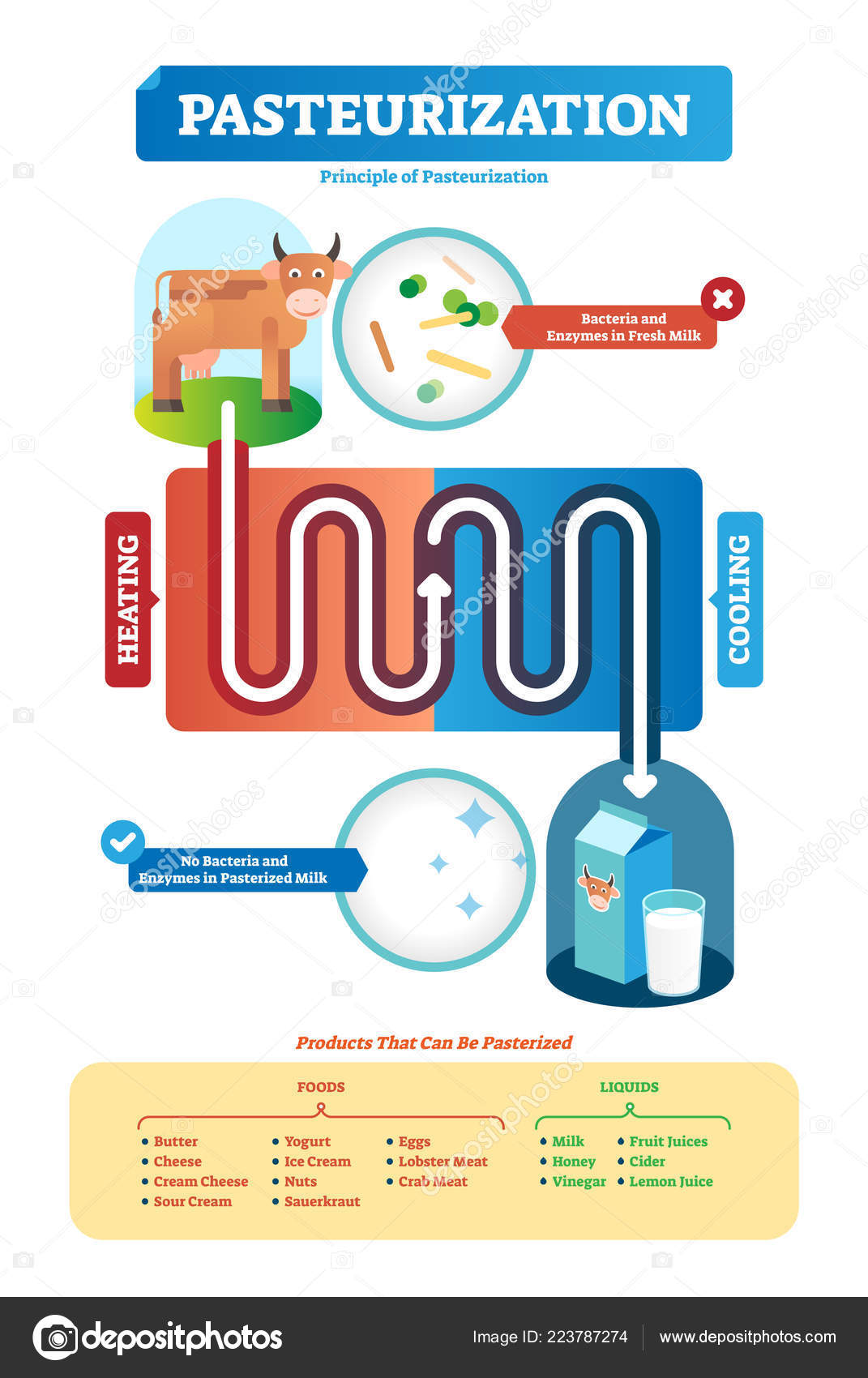

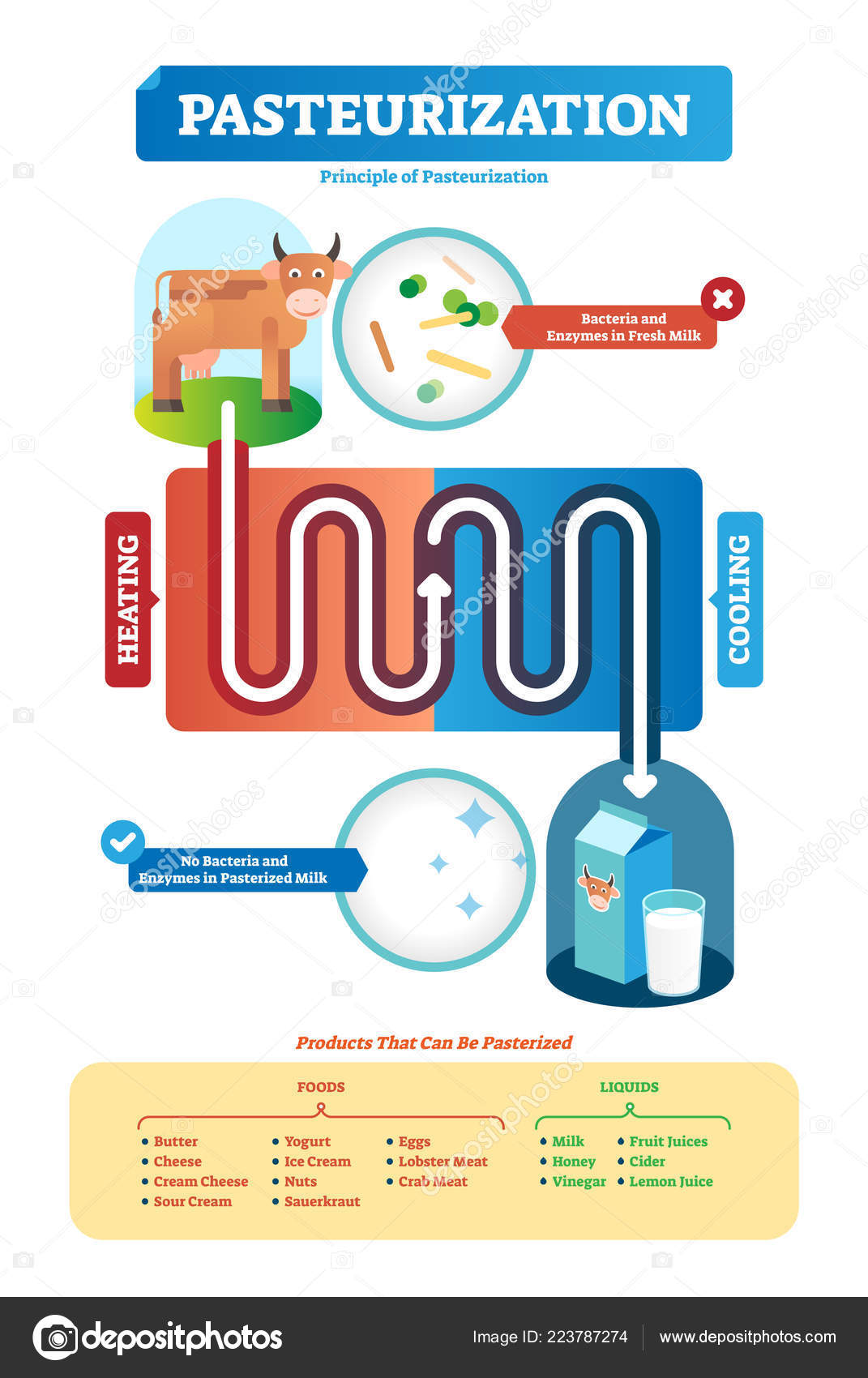

The Tunnel pasteurizer procedure gets rid of residual germs from food and also drinks. They are effective and be available in different dimensions to fit different requirements. They are used in the food as well as drink markets to kill microorganisms, stop fermentation, as well as supply rack stability. Nevertheless, they undergo high mechanical stress and temperature variants, and damaged bottles can create damages to the devices. PRO Engineering/Manufacturing has actually been supplying the market with high quality Tunnel pasteurizers for years and also has actually constructed several kinds and dimensions.

Tunnel pasteurization serves for carbonated beverages, which may have a lengthy shelf life in between production and also intake. Some beverages remain on racks for weeks before being taken in. They can additionally take a trip long distances, spending a duration in a cupboard or fridge after acquisition. For this reason, Tunnel pasteurization aids keep quality and flavor of these drinks. The procedure is likewise helpful for breakable packaging, consisting of glass and light weight aluminum canisters. The sudden change in temperature level can result in the tear of these containers, which makes it necessary to apply the necessary preventative measures.

Tunnel Pasteurizers can be used to sterilize drinks without chemicals. They use a warmth resource, raising the number of temperature zones and minimizing microbes. The temperature level is elevated until the needed pasteurization temperature level is attained. When the pasteurization procedure is complete, the beverage is cooled down to stop any kind of prospective damage.

Tunnel Pasteurizers are not only used in beverage production, yet additionally in the beer market. Its heat exchange function aids recoup energy through different temperature zones. Its maximized nozzle system ensures excellent heat exchange with the item. Furthermore, Tunnel pasteurizers feature water-saving features. They gather the water collected during the pasteurization procedure, while also preserving high sanitary standards.

Tunnel Pasteurizers are a suitable selection for large-scale production processes. These systems are an affordable, user friendly alternative to sterilized filtration and also flash pasteurization. They can likewise stop wear and tear of flavor. Some designs feature automated stop systems to stop overpasteurization. They likewise are available in different dimensions as well as dimensions. They can be personalized to fulfill details customer needs.

Temperature sensors are an essential feature of pasteurization units. try this web-site are made use of to figure out the pasteurization values. These measurements are done utilizing a formula that determines the PUs. Tunnel Pasteurizers are able to keep an eye on the water temperature with high accuracy. In addition, they are made for long-lasting use. For the best results, temperature sensing units need to be positioned at crucial points. Furthermore, calibration systems ought to tape-record temperature and pressure within the process distribution system.

A passage pasteurizer can be utilized for large productions that have high filler prices. In these instances, a passage pasteurizer is required to prevent germ exposure to the downstream equipment. Using this technology will enable production lines to maintain the best standards and remove danger of contamination.

They are ergonomic and lasting, as well as they utilize an unique control software to maximize effectiveness as well as lower water use. This makes sure a high level of sanitary performance. The compact design supplies very easy availability to the parts, allowing for very easy cleaning and also substitute of inlet displays. Tunnel Pasteurizers can additionally be made use of in mix with hot filling up techniques, consisting of warm filling innovation.

The Tunnel pasteurizer procedure gets rid of residual germs from food and also drinks. They are effective and be available in different dimensions to fit different requirements. They are used in the food as well as drink markets to kill microorganisms, stop fermentation, as well as supply rack stability. Nevertheless, they undergo high mechanical stress and temperature variants, and damaged bottles can create damages to the devices. PRO Engineering/Manufacturing has actually been supplying the market with high quality Tunnel pasteurizers for years and also has actually constructed several kinds and dimensions.

Tunnel pasteurization serves for carbonated beverages, which may have a lengthy shelf life in between production and also intake. Some beverages remain on racks for weeks before being taken in. They can additionally take a trip long distances, spending a duration in a cupboard or fridge after acquisition. For this reason, Tunnel pasteurization aids keep quality and flavor of these drinks. The procedure is likewise helpful for breakable packaging, consisting of glass and light weight aluminum canisters. The sudden change in temperature level can result in the tear of these containers, which makes it necessary to apply the necessary preventative measures.

Tunnel Pasteurizers can be used to sterilize drinks without chemicals. They use a warmth resource, raising the number of temperature zones and minimizing microbes. The temperature level is elevated until the needed pasteurization temperature level is attained. When the pasteurization procedure is complete, the beverage is cooled down to stop any kind of prospective damage.

Tunnel Pasteurizers are not only used in beverage production, yet additionally in the beer market. Its heat exchange function aids recoup energy through different temperature zones. Its maximized nozzle system ensures excellent heat exchange with the item. Furthermore, Tunnel pasteurizers feature water-saving features. They gather the water collected during the pasteurization procedure, while also preserving high sanitary standards.

Tunnel Pasteurizers are a suitable selection for large-scale production processes. These systems are an affordable, user friendly alternative to sterilized filtration and also flash pasteurization. They can likewise stop wear and tear of flavor. Some designs feature automated stop systems to stop overpasteurization. They likewise are available in different dimensions as well as dimensions. They can be personalized to fulfill details customer needs.

Temperature sensors are an essential feature of pasteurization units. try this web-site are made use of to figure out the pasteurization values. These measurements are done utilizing a formula that determines the PUs. Tunnel Pasteurizers are able to keep an eye on the water temperature with high accuracy. In addition, they are made for long-lasting use. For the best results, temperature sensing units need to be positioned at crucial points. Furthermore, calibration systems ought to tape-record temperature and pressure within the process distribution system.

A passage pasteurizer can be utilized for large productions that have high filler prices. In these instances, a passage pasteurizer is required to prevent germ exposure to the downstream equipment. Using this technology will enable production lines to maintain the best standards and remove danger of contamination.